-

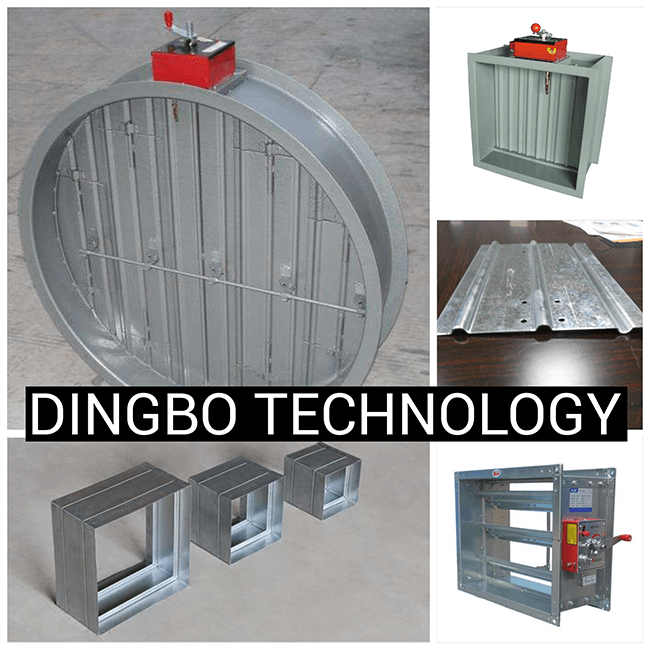

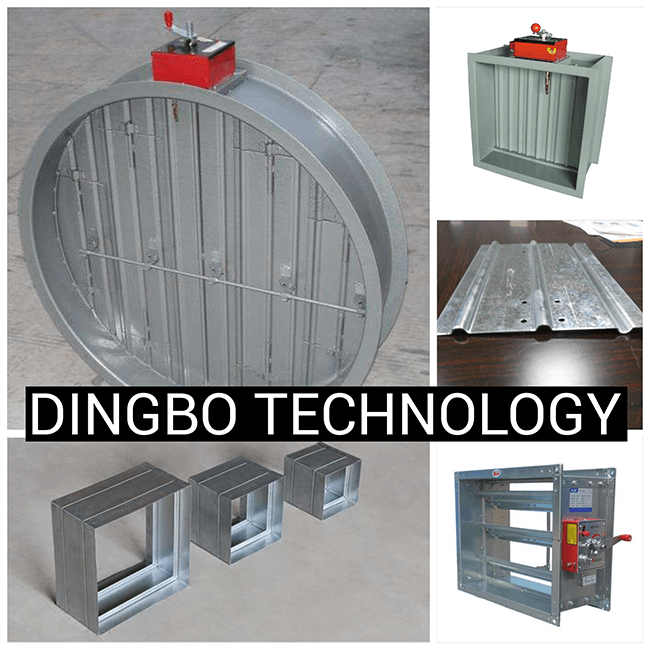

The Fire Smoke Vane Damper produced by the Fire Smoke Vane Damper Roll Forming Machine is installed on the exhaust system pipe (located on the pipe at the suction port of the exhaust fan), and in addition to the function of the exhaust valve, it has a fuse when the exhaust gas temperature exceeds 280℃, so that The valve is closed and the smoke exhauster is shut down at the same time.

-

Customers can choose the right equipment according to their own and market needs. The automatic production line of fire damper adopts modular design, PLC control, touch screen operation, easy to learn, no welding, no need for painting, saving cost, saving manpower, greatly improving the production efficiency of fire damper, and is an essential equipment for mass production of fire dampers.

-

Working Flow: Decoiler -- Feeding -- Straighten -- Punching -- Roll forming -- Shear -- Output table

Version to design

|

Main motor power |

15kw |

|

Drive |

Chain |

|

Main shaft diam |

76mm( material: 45#forge steel and quenched ) |

|

Roller material |

Gcr15 bearing steel forge steel and quench treatment hardness 58-62, chrome coated 0.05mm |

|

Roll station |

12 groups |

|

Raw material |

0.8~2.0mm |

|

Width of purlin |

100~500mm adjustable |

|

Working speed |

10m--15m/min(Exclude cutting time) |

|

Length Tolerance |

±1mm |

|

Weight of machine |

about 6ton |

|

Size of machine |

About 9000×1000×1500mm L x W x H |

|

Color of machine |

depend on customer |

|

Coder |

Omron |

|

Control |

PLC Panasonic, made in Japan. 380V 50HZ |

|

Computer operating panel |

touching screen |

|

Punching |

Hydraulic punching before roll forming |

|

Cutting |

Hydraulic cutting after roll forming( Cutting when reach the set length ) |

|

Hydraulic power |

5.5KW |

|

Blade material |

Cr12,quenched 58°-62° |

|

Working pressure |

20mpa |

|

Cutting tolerance |

+/- 1.5mm |

Main Components

-

No.

Name

Qty

1

Manual Decoiler

1

2

Punching part

1

3

Main roll forming machine

1

4

PLC Control box

1

5

Hydraulic station

1

6

Post cut

1

7

Output table

1

-

Pictures