-

M Purlin is widely used in steel structures such as purlins and wall beams. It can also be combined into building components such as roofs and supports with light weight. It can be used for light manufacturing of mechanical columns, beams and walls. M purlin is formed by roll forming of hot-rolled sheets, and is not deformed by the balance of stress during the forming process. It has the characteristics of light weight, good cross-section performance and high strength.

-

Working Flow: Manual Decoiler -- Punching -- Roll-forming -- Cutting to length -- Output table

-

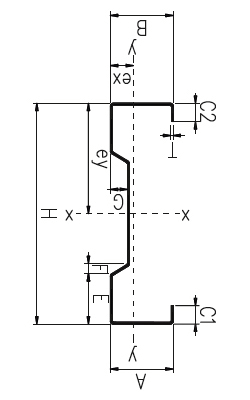

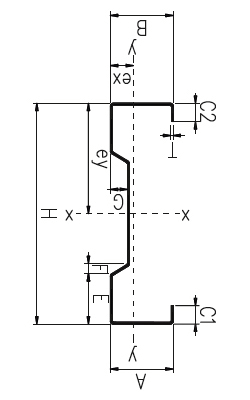

Profile Design

|

|

Items |

Specifications |

|

Material of coil |

Purlin Width |

As per design |

|

Purlin Height |

As per design |

|

|

Material Thickness |

1.5-3mm |

|

|

Uncoiler |

5 tons manual |

|

|

Leveling |

7Rollers |

3upper rollers, 4 lower rollers |

|

Hydraulic |

Hydraulic Power |

5.5kw |

|

Punching |

Pre-punching |

|

|

Punching mould material |

Cr12Mov |

|

|

Forming system |

Rolling Speed |

10-15m/min |

|

Roller Stations |

14 stations |

|

|

Roller Material |

Gcr15, quench treatment hardness 55-58 |

|

|

Shaft material |

45#steel |

|

|

Main Motor Power |

18.5kw |

|

|

Way Of Drive |

Chain |

|

|

Hydraulic |

Cutting |

Post-cutting |

|

Blade Material |

Cr12Mov |

|

|

Blade |

3 pieces |

|

|

Tolerance |

+-1.5mm |

|

|

Electrical control system |

Electric Source |

380V, 50HZ,3 phase(customized) |

|

PLC Control System |

Siemens |

Main Components

-

No.

Name

Qty

1

Manual Decoiler

1

2

Hydraulic Punching

1

3

Main roll forming machine

1

4

PLC Control System

1

5

Hydraulic station

1

6

Output table

2