-

Technological process: Decoiler—Feedingwithguide—Cutting —Rollforming—Products collecting

|

|

Items |

Specifications |

|

|

Material of coil |

Material Thickness |

03-0.8mm PPGI and AL |

|

|

De-coiler |

5 ton hydraulic |

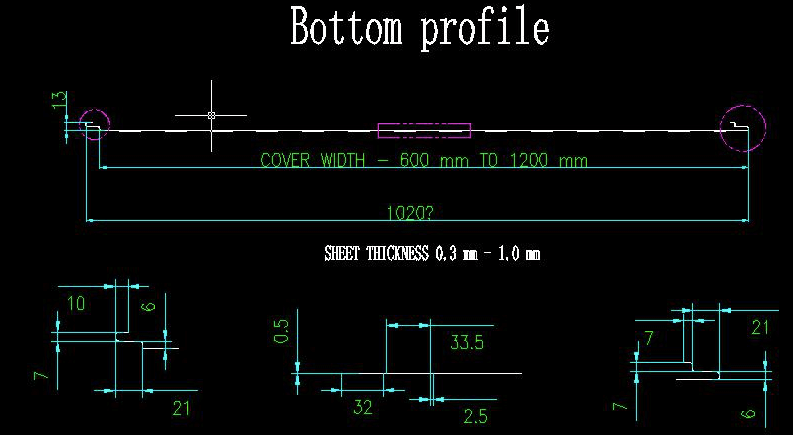

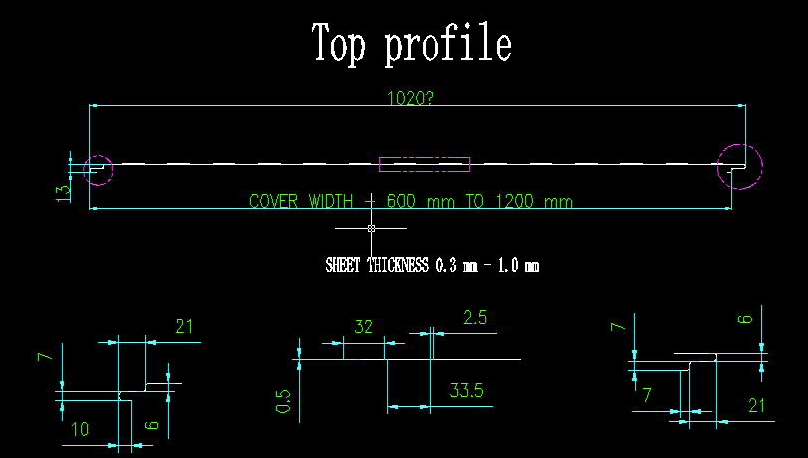

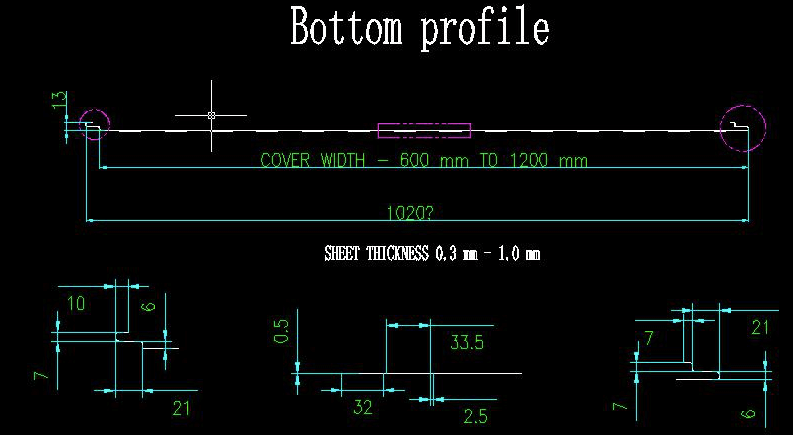

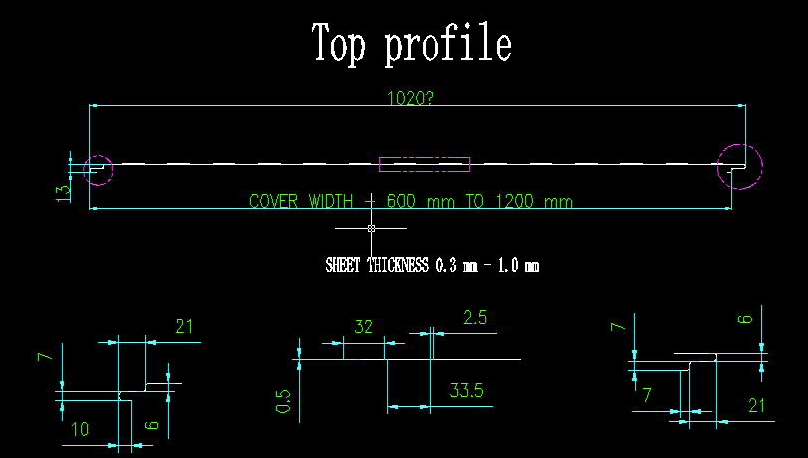

Finished width from 600-1200mm adjustable |

|

|

Forming system |

Rolling Speed |

10-12 m/min |

|

|

Roller Stations |

About 18 stations |

||

|

Roller Material |

Gcr15 Steel with quenching |

||

|

Shaft Material |

45# Steel Diameter 75mm shaft |

||

|

Maim Motor Power |

7.5 kw |

||

|

Hydraulic cutting Power |

4 kw |

||

|

Moving- |

LM rail |

||

|

Cutting |

Hydraulic Rexroth |

system-Bosch |

|

|

Material Of Cutting |

CR12 with quench treatment |

||

|

Hardness |

HRC58-62 |

||

|

Tolerance |

+-1.5mm |

||

|

Electrical control system |

Electric Source |

380V, 50HZ,3 phase |

|

|

Control System |

PLC Panasonic |

||

|

Program |

English and Chinese |

||

|

Sensor |

Omron |

||

|

Relay board |

Panasonic |

||

|

Switchgear |

Schneider |

||

|

Touch screen |

Beijing Kunlun |

||

|

General info |

Weight |

About 4.5 tons |

|

|

Way Of Drive |

1 inch single chain |

||

|

Size of machine |

Length 7500mm* Width 1500mm*Height 1000m |

||

Main Components

-

No.

Name

Qty

1

Decoiler

1

2

Main roll forming machine

1

3

PLC Control box

1

4

Hydraulic station

1

5

Output table

2

-

Pictures

-

Pictures