-

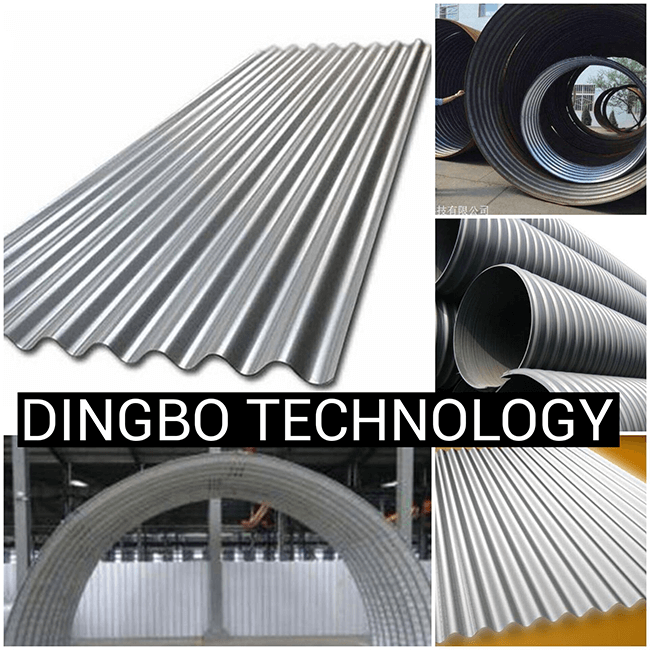

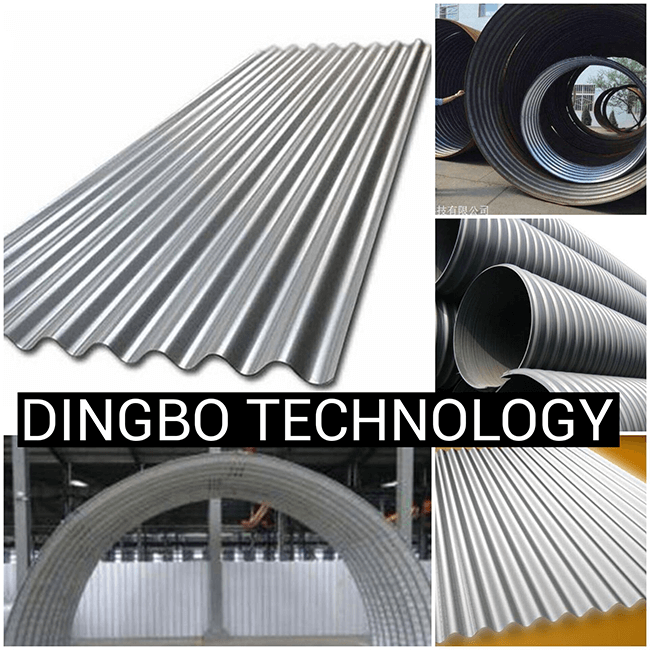

The Barrel Corrugated Roll Forming Machine can process galvanized steel plate, which is made of products with beautiful appearance and smooth lines. It is mainly used for interior and exterior walls and floor panels of industrial and civil buildings. It has large peaks, high strength and installation points. After welding the steel mesh, it is combined with concrete on-site watering and has good adhesion. In the high-rise building, the steel formwork can be omitted and the floor load can be reduced. Under the premise of equal bearing capacity, the amount of engineering steel is reduced, and the quantitative input cost is saved.

-

Working Flow: Decoiler → Roll forming → Cutting → Auto stacker

Version to design

|

Suitable material |

Color steel sheet |

|

Material thickness |

0.3-0.8mm |

|

Forming speed |

10-15m/min |

|

Main motor power |

5.5 Kw(Depend on final design) |

|

Hydraulic cutting power |

3 Kw(Depend on final design) |

|

Roller material |

45#steel Chrome Plated |

|

Cutting blade material |

Cr12 Mould Steel |

|

Shaft material |

High quality 45# steel with heat treatment. |

|

Shaft diameter |

76mm |

|

Control system |

PLC with touch screen(Panasonic/Siemens) |

|

Machine’s size |

About 10.5m×1.8m× 1.5m (Depend on final design) |

Main Components

-

No.

Name

Qty

1

Decoiler

1

2

Main roll forming machine

1

3

PLC Control box

1

4

Hydraulic station

1

5

Auto stacker

1

-

Pictures