-

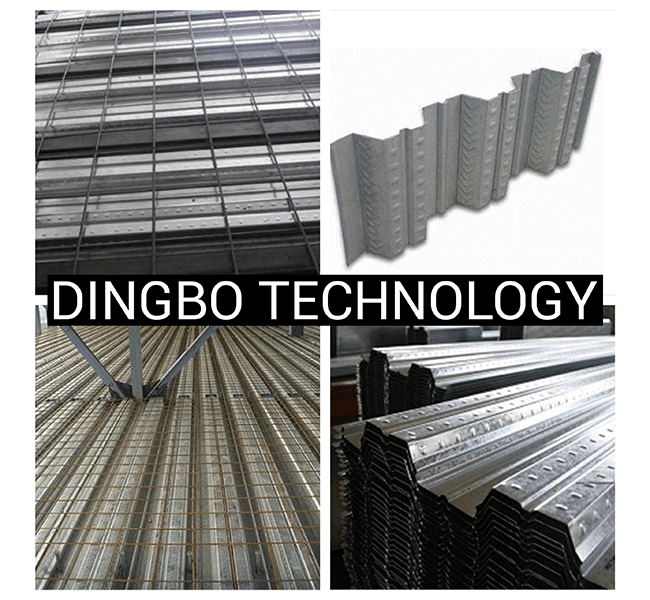

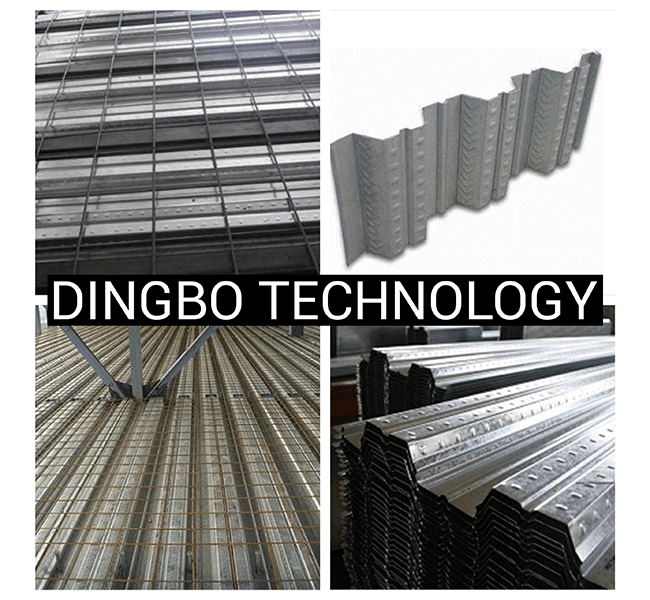

The Deck Floor roll forming machine with reasonable structure and beautiful appearance. It has the characteristics of saving floor space and simple operation, and is especially suitable for customers with small site and on-site construction.

-

Widely used in the field of multi-story steel structure construction, mainly used for the floor plane. It adopts hot-dip galvanized steel sheet to be formed by rolling cold bending, and the upper and lower layers are easy to switch. It only needs to be converted by the conversion button on the electric control cabinet to control each layer separately, and the power can also control each layer through the clutch. The optional equipment is equipped with a common discharge machine and a hydraulic discharge machine. The model of the upper and lower layers is subject to customer requirements.

-

Working Flow: Auto decoiler -- Feeding -- Roll forming -- Hydraulic cutting -- Output table

Version to design

|

Type |

Double-layer floor deck roll forming machine |

|

Thickness |

0.8mm-1.6mm |

|

Feeding Width |

1220mm |

|

Frame Design |

Wall-plate-frame-design /New-stand-frame-design |

|

Roll Stages |

28 stages |

|

Material Of Forming Roller |

45# steel, CNC lathes, Hard Chrome Coated |

|

Shafts Diameter |

Φ95mm |

|

Main Motor Power |

15KW×2 with reducer |

|

Max. Line Speed of Roll Former |

15m/min (Higher speed is available, depends on the specification required by the buyer) |

|

Hydraulic Group Power |

5.5KW |

|

Material of Cutting Blade |

Cr12, hear treatment |

|

Electric Standard |

380V /50Hz/3PH or as per customer's requirements |

|

Machine Dimensions |

part A+B:11200mm*2080mm*1050mm / Part C: 7000mm*2050mm*1700 mm |

|

Major Color of Machine Painted |

RAL 5015 (Blue) or as per customer’s requirements |

Main Components

-

No.

Name

Qty

1

Decoiler

1

2

Main roll forming machine

1

3

PLC Control box

1

4

Hydraulic station

1

5

Output table

2

-

Pictures