-

The floor deck roll forming machine is used for floor panels with high strength and good adhesion. In the high-rise building, the steel formwork can be omitted and the floor load can be reduced. Under the premise of achieving the same bearing capacity, the amount of engineering steel can be reduced, thereby saving input costs.

-

1. The structure is simple and the appearance is beautiful. Because the whole machine adopts the steel structure and the whole processing after welding, the structure is simple and reasonable, the bearing capacity is strong, and the operation is stable and reliable. Large equipment customized for thick plates.

-

2. Set other important components and components to use domestic or imported famous brand accessories to ensure the performance of the equipment.

-

3. Equipment installation and debugging is convenient, easy to operate

-

4. Low noise, no pollution, low consumption

-

Working Flow: Auto decoiler -- Feeding -- Roll forming -- Hydraulic cutting -- Output table

Version to design

|

Size |

13000*2200*1500mm |

|

Weight |

16000KGS |

|

Voltage |

380V/60HZ/3PH |

|

Hydraulic Motor Power |

22KW |

|

Forming Steps |

23-28 steps |

|

Working Speed |

10-15m/min |

|

Forming Steps |

Φ95mm |

|

Rib Height of Decking |

45mm |

|

Effective Width |

975.8mm |

|

Material Width |

1220mm |

|

Thickness for common use and test machine |

0.8-1.2mm-1.6mm |

|

Tolerance |

±0.05mm |

|

Roller material |

45# steel with hot treated |

|

Material of shaft |

High grade 45# forged steel |

Main Components

-

Decoiler / Uncoiler

1 Unit

Feeding Guide

1 Unit

Roll Forming Machine

1 Unit

Hydraulic Cutting Device

1 Unit

Hydraulic Station

1 Unit

PLC Computer Control Board

1 Unit

Runout Tables

2 Units

-

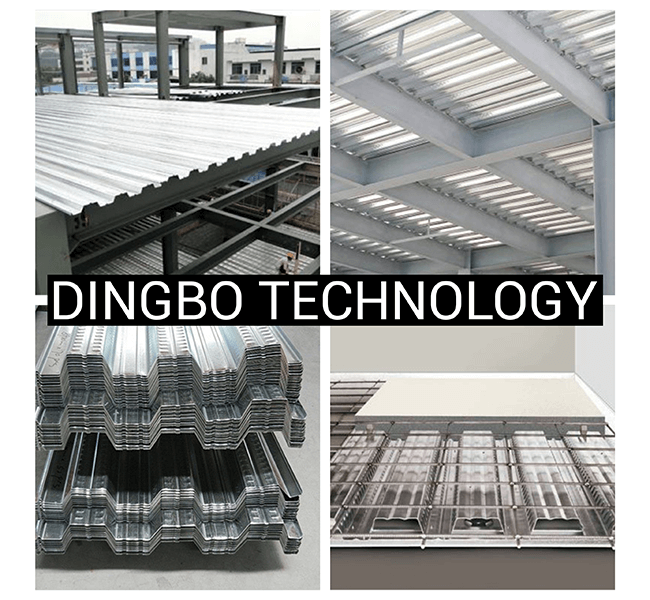

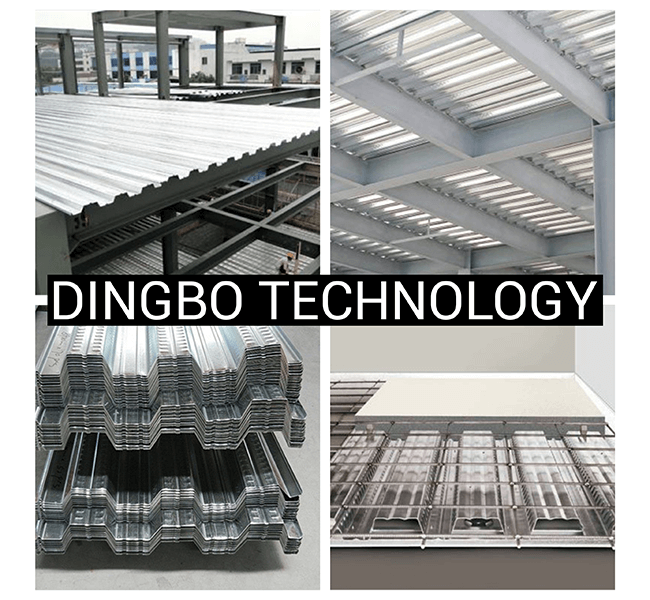

Pictures