-

Pallet Rack Roll Forming Machine, Rack shelf roll forming machine, rack column roll forming machine - rack roll forming machine, Rack post roll forming machine, rack roll forming machine, rack roll forming machine, rack column forming machine, rack post roll forming machine includes decoiler, feeding and levelling device, roll forming machine, flying saw cutter, run-out table, hydraulic system and PLC control system, etc. We produce series of machines for rack upright, column, beam, angle steel, and other racking profiles.

-

Working flow: Decoiler --- Servo Feeding --- Punching--- Levelling--- Roll Forming ---- Cutting ---- Run out table

-

1. Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or blank steel

2. Working Speed: 12-15 meters / min

3. Forming Steps: 18 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

6. Driven system: Chain Driven 1.5 inches 20A

7. Main Power with reducer: 11KW WH Chinese Famous

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 7.5KW Wuxi Wanshen Famous Chinese Brand

11. The whole machine is controlled by industry computer-PLC

12. PLC--Panasonic, Japan English and Chinese Language

13. Touch Screen--Panasonic Japan

14. Encoder--Omron, Japan

15. Electric parts--Schneider

|

Decoiler (manual and automatic for options) |

1 set |

|

Guiding device |

1 set |

|

Leveling system |

1 set |

|

Punching system |

1 set |

|

Roll Forming system |

1 set |

|

Hydraulic Cutting system |

1 set |

|

PLC control box |

1 set |

|

Hydraulic unit |

1 set |

|

Run outs tables |

1 set |

-

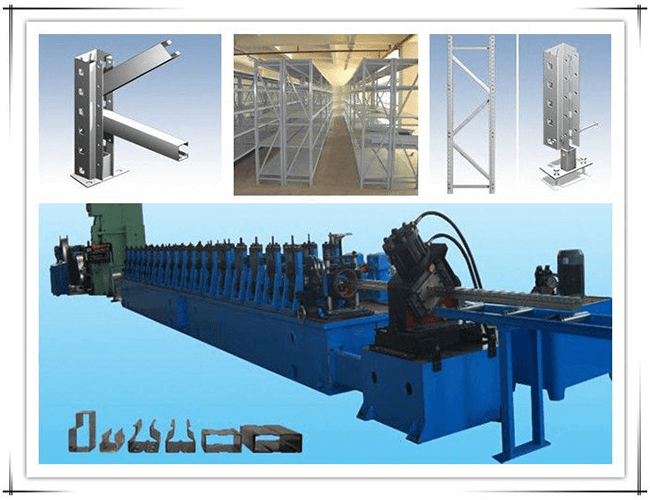

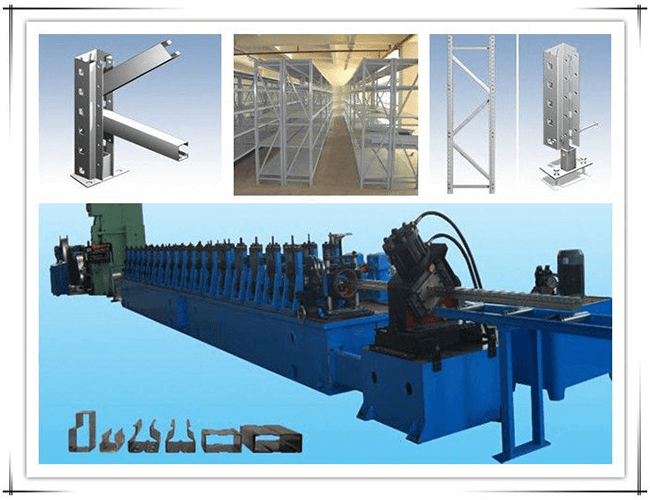

Machine pics

-

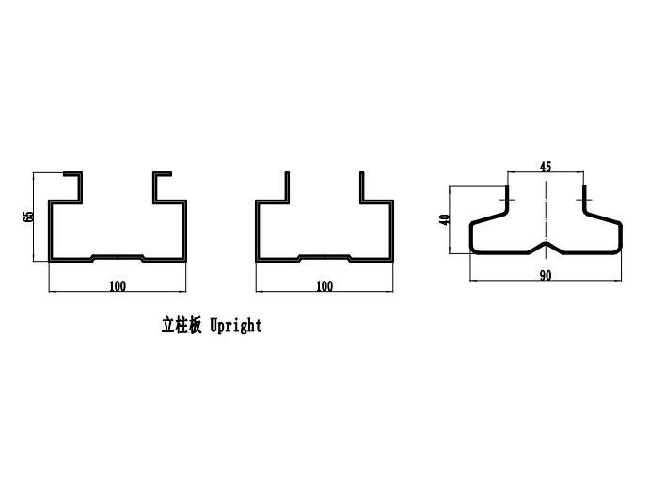

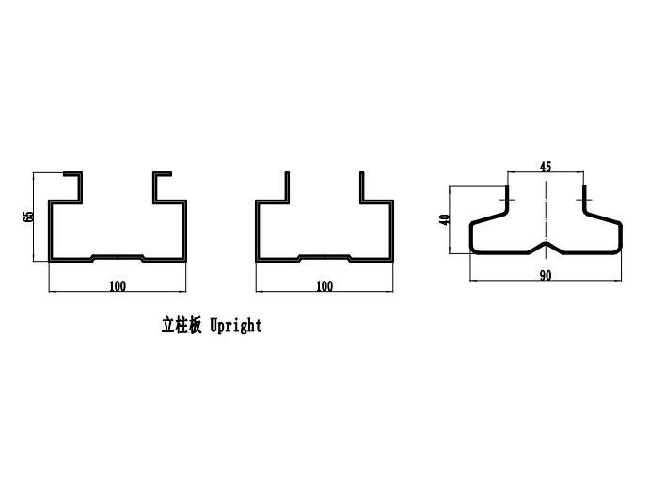

Profile drawing