-

Square Pipe Roll Forming Machine include Step Beam Roll Formng Machine. Beam rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. And square pipe can be used as down pipe also. Normally thickness can be formed at 1.5-3mm and the speed is about 10-20m/min.This machine is widely used in high warehouses.

-

Working flow: Uncoiler——Leveler & feeding--Roll Forming—High Frequency Welder/Argon arc welding--Flying Saw Cutting—Output table

|

Warehouse Step Beam/Square Pipe Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, |

|

|

Thickness(mm):1.5-1.8,1.5-3 |

|||

|

Yield strength: 250 – 550MPa |

|||

|

Tensile stress(Mpa): |

|||

|

2 |

Nominal forming speed(m/min) |

10-20 |

Or according to requirement |

|

3 |

Forming station |

31 |

|

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Chain drive |

Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Torri stand structure |

Forged Iron stationOr Wall panel station |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

-

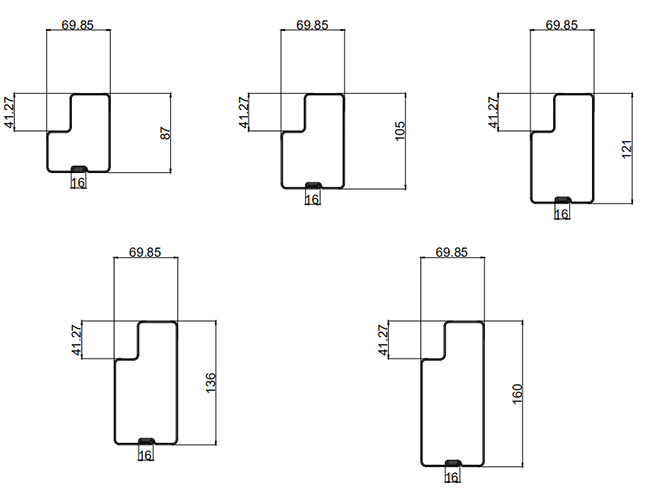

Profile drawing

-

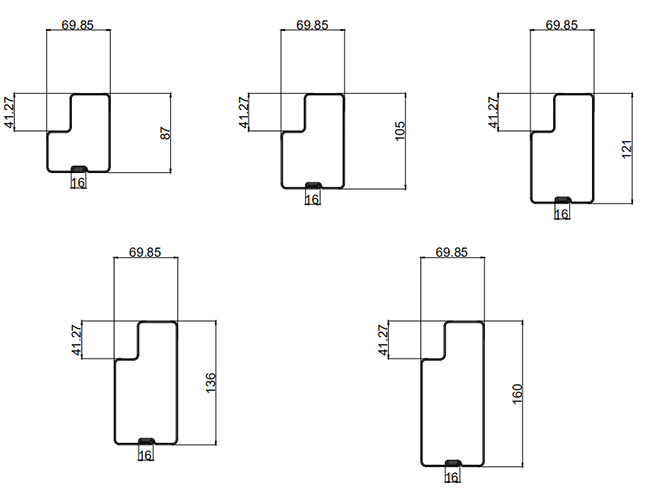

Profile drawing