-

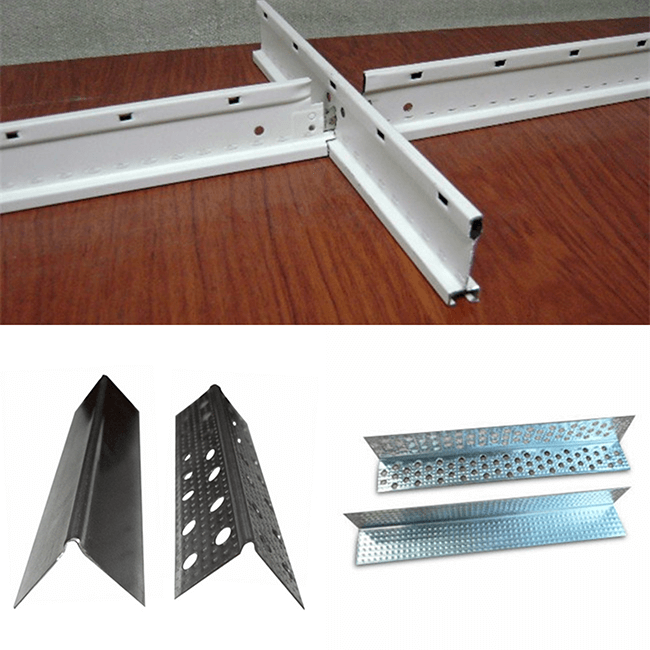

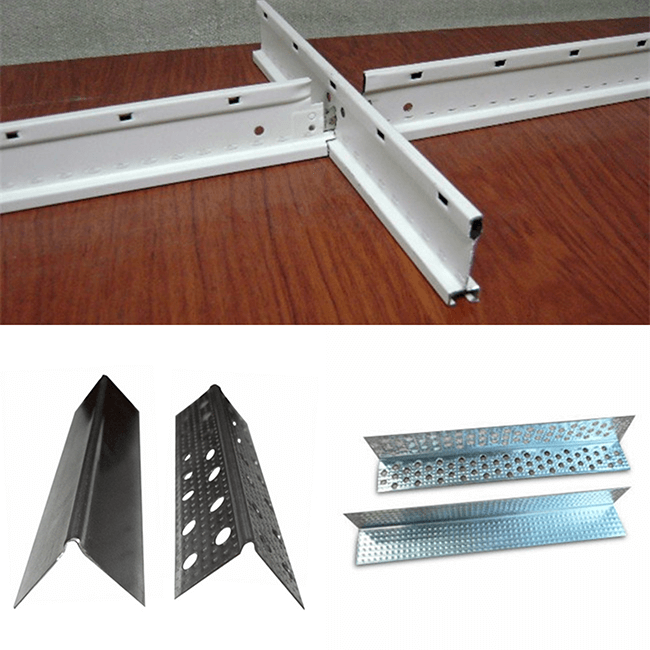

V-type hanging keel, also known as Wall angle keel, breaks the traditional form of ceiling keel in design and manufacture, and uses high-quality snowboard as raw material, which has strong fireproof, rust-proof and anti-aging properties.

-

The detection, the construction is convenient, the effect is outstanding, and it is widely used in modern decoration engineering.

-

The two sides of the V-shaped groove are symmetrically and orderly arranged with an anchor-like hook. The hook can be formed into an imperial or metric combination with the auxiliary keel. The main keel and the auxiliary keel are connected with an eight-centimeter screw to make it stronger and durable.

-

Working Flow: Decoiler--Guiding-- Roll-forming--Hydraulic cutting -- Output table

Version to design

|

Items |

Specifications |

|

Material Thickness |

0.4-0.8 mm galvanized sheet G550 |

|

Rolling Speed |

About 20 m/min line speed |

|

Roller Stations |

About 9 stations |

|

Roller Material |

45# Steel with quenching 60mm shaft |

|

Maim Motor Power |

5.5 kw |

|

hydraulic station Power |

4 kw |

|

Material Of Cutting |

CR12 with quench treatment |

|

Tolerance |

+-1.5mm |

|

Electric Source |

380V, 50HZ,3 phase |

|

Also can satisfy Customer’s require |

|

|

Control System |

PLC control system |

|

Weight |

About 2.5 tons |

|

Way Of Drive |

1 inch single chain |

|

Size of machine |

Length 4500mm* Width 500mm* Height 800m |

Main Components

-

No.

Name

Unit

Qty

1

Manual decoiler

set

1

2

Punching part

set

1

3

Main forming machine

set

1

4

PLC control system

set

1

5

Hydraulic pump station

set

1

6

Post cut

set

1

7

Electric motor

set

1

8

Output table

set

1

-

Pictures